Good day, today I’m continuing to work on the fuel sending units. Part of finishing off the installation of the sender plates, was that I needed to install the anti-hang up brackets in the root rib bay for the flop tube. While doing this, I also needed to make sure that the flop tube didn’t get hung up on the lower skin stiffeners.

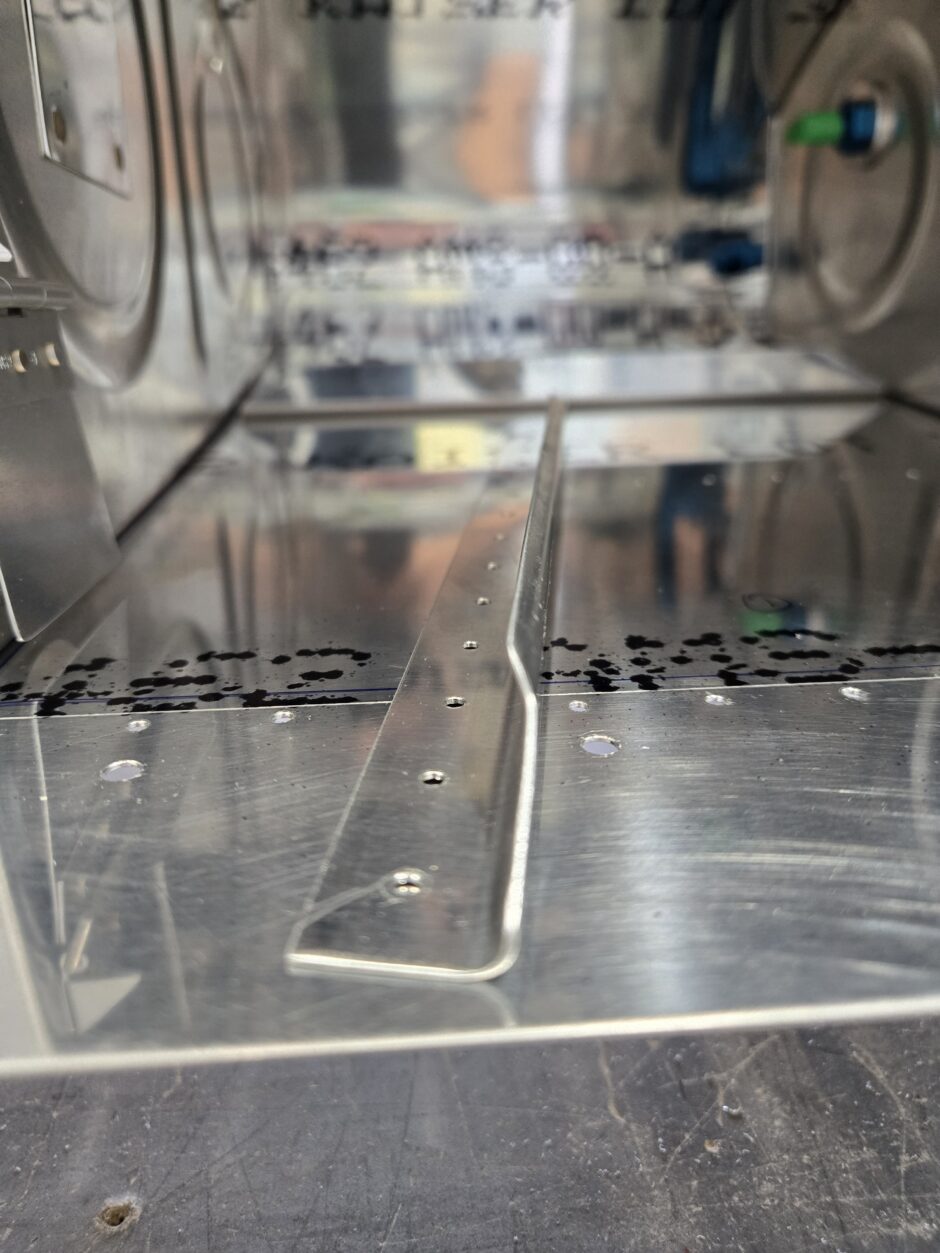

In this case, my flop tube end fittings were able to get hung up on the stiffeners. The solution I found was to round off the upper end of the most aft stiffener.

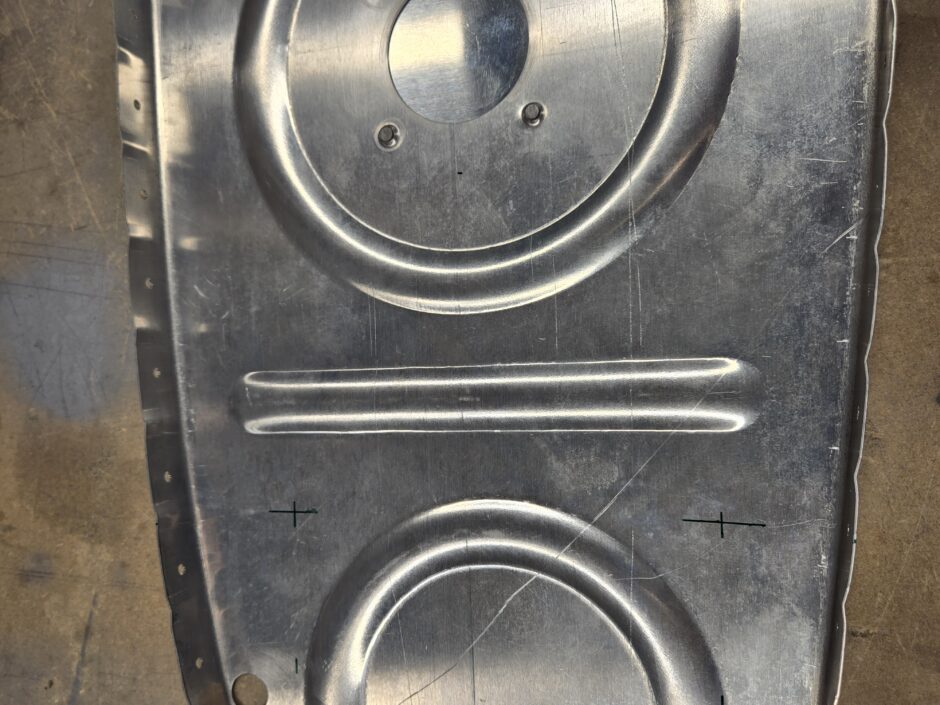

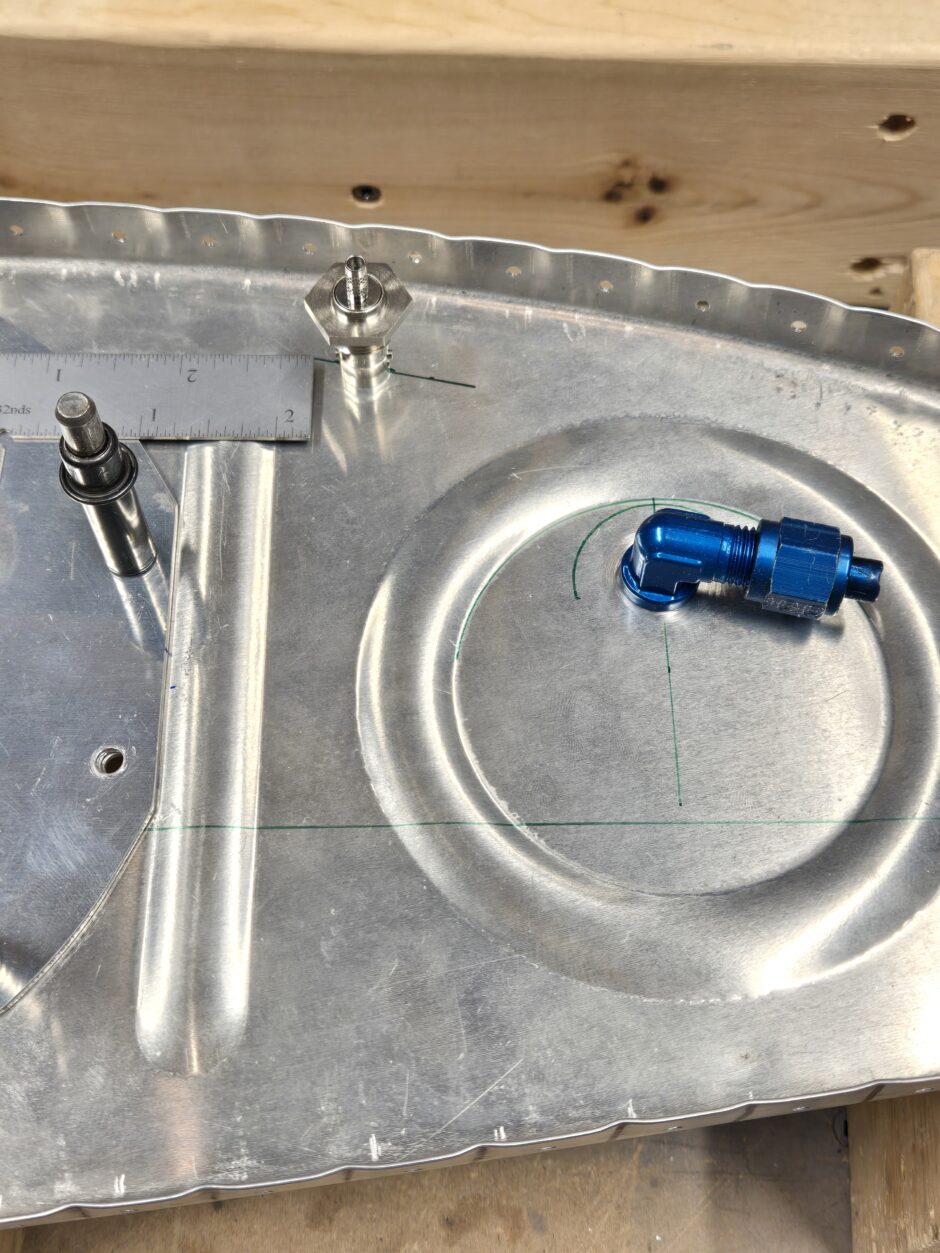

With the flop tube not getting hung up anymore, I moved on to mounting the inboard fuel sender plate. I need to get this plate located before I’m able to sort out where to mount the anti-hang up bracket in the root bay.

Below, the 3 mounting points have been transcribed by measurement from the sender plate onto the rib.

I’m hopping all over today, but I also needed to install the BNC connector for the sender system.

Okay…getting back on track now with the sender plates, when I was happy with the location of the plate, I drilled the plate to the rib.

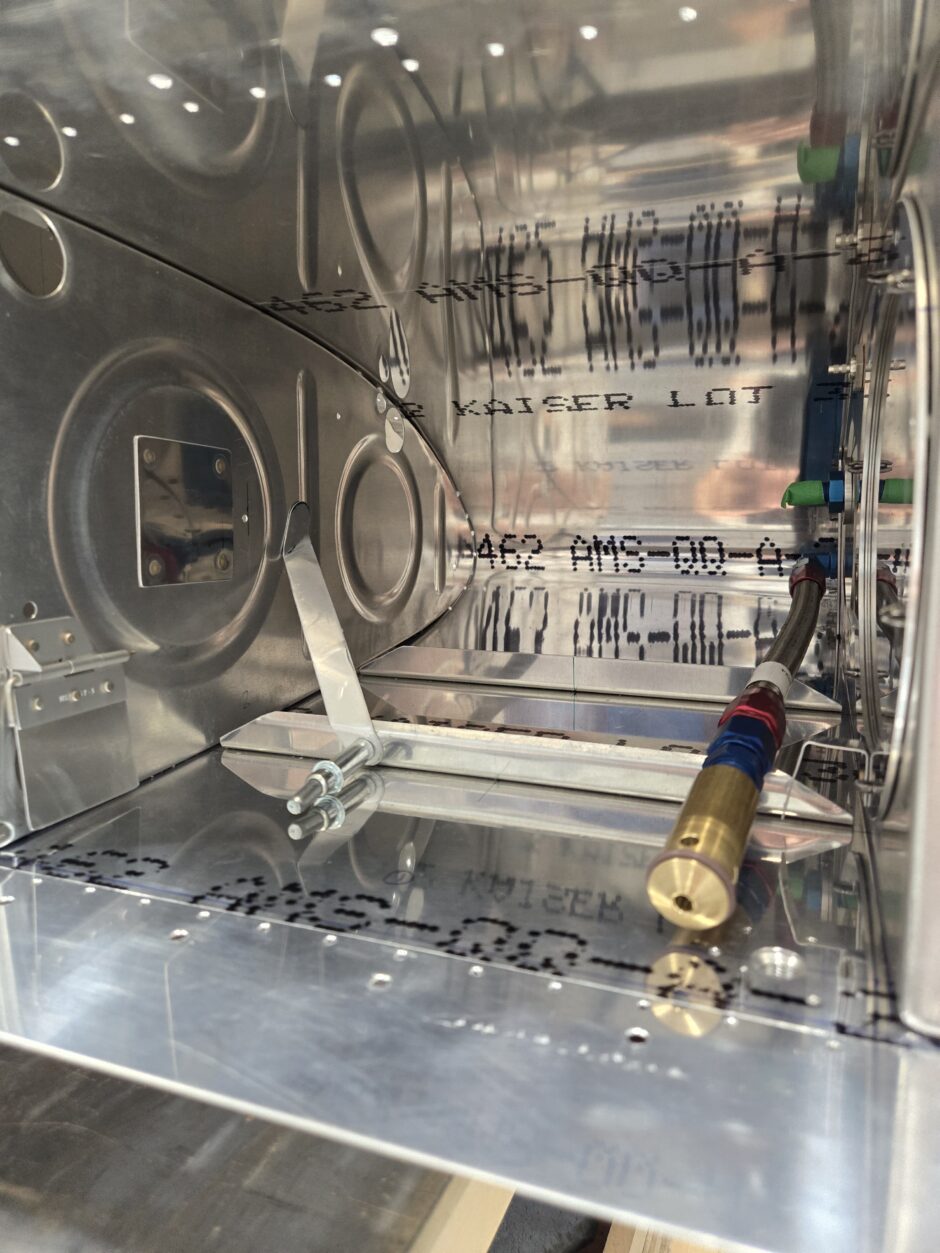

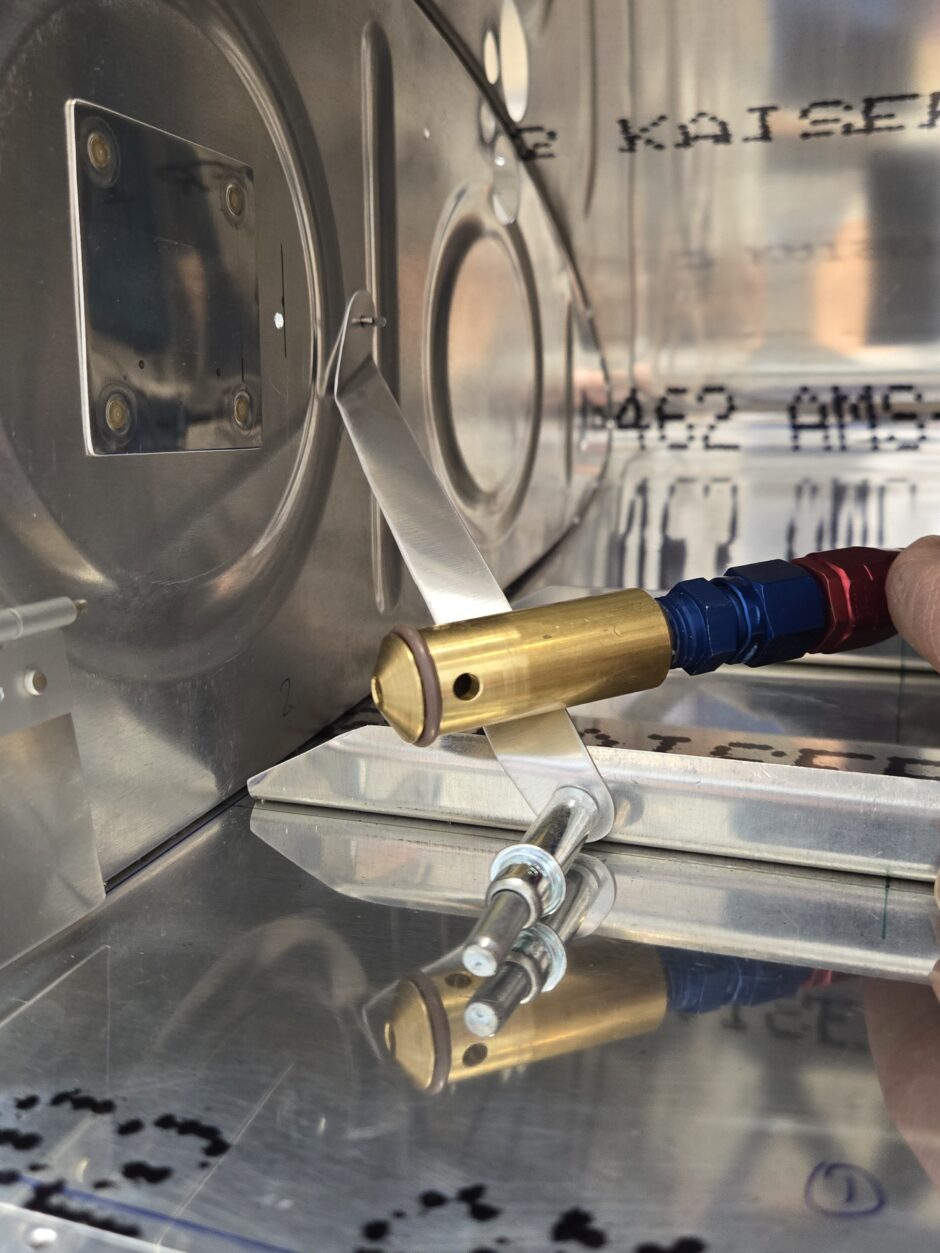

Now, with the sender plate mounted, I was finally able to start getting the anti-hang up bracket mounted. As you can see, the upper end of the bracket is located quite close to the aft mounting fastener for the sender plate. I chose to mount the bracket just forward of the sender’s rear mounting hole.

The pictures below show how the anti-hang up bracket prevents the flop tube from getting stuck behind the lower skin stiffener.

And here’s the flop tube on the upper side of the bracket.

I also wasn’t working alone today, I had my besties faithfully and patiently waiting at the shop door for me. As much as I’d love to have them in the shop with me, there are just too many metal chips, filings and other metal swarf that I don’t want them to hurt their paws on.

That’s all for today folks! Please comment. I love to hear from my readers. Thanks again for coming along for this ride, you make my work worthwhile.

Leave a Reply