Today I ventured into cutting the HS-3201 horizontal stabilizer forward spar doubler.

Drilling

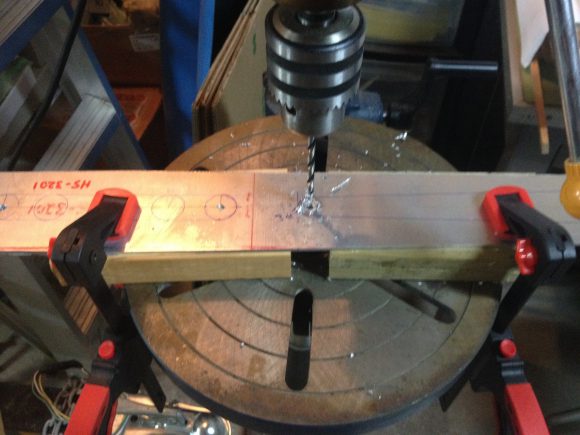

I started by securely clamping the doubler plate onto the drill press. I located the center of the holes to be cut.

Once the holes were located, I used larger drill bit to cut the holes to size. It was a toss-up whether or not to use a hole saw bit or the large drill bit. As I couldn’t find the right size hole saw I picked up the large drill bit and it worked like a charm.

Once the end holes were cut, it was time to remove the material in between. Think of this as a large tab to be removed. To do this I clamped the doubler plate to the workbench and used a jig saw fitted with a metal cutting blade. Some other tricks used here to help the cutting process were going pretty slow with the saw, and using lots of Boelube (stick applicator) on both the saw blade and the line to be cut along.

In the image below you can now see the lightning hole in the center of the doubler plate has been cut and the outer forks have also been cut. This process went very smoothly and I’m happy with the results. What I don’t look forward to is the filing needed to smooth out all the rough edges and tooling marks left by the jigsaw blade, but that is another adventure for another day.

Please comment, I love to hear from my readers. Thanks again for coming along for this ride, you make my work worthwhile.

Leave a Reply