Today I began with dimpling the VS-803PP rear spar. For dimpling I use the DRDT-2 dimpling machine. This is one of the “Must Have” tools. Yes, it is an expensive piece of kit but it is well worth it; not only in consistency of the dimples but also in being able to work quietly. As I am conducting this work in a basement apartment, excessive noise is a big factor that I need to me conscious of.

Here is a picture of how the dimples on the VS-803PP and countersinking on VS-808PP spar doubler interface each other.

VS-803PP Riveting

Once the dimpling of the VS-803PP rear spar was done, I was able to move on to riveting. All my riveting today was accomplished with using the Main Squeeze that I got from Cleveland Tools. Most handheld rivet squeezers are pretty useless. The Main Squeeze is an entirely different beast and it works amazingly well. Again, money well spent.

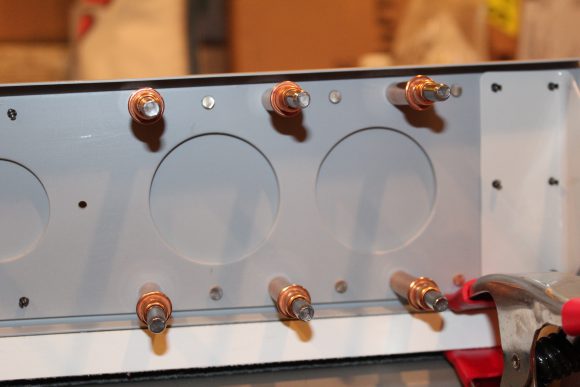

Here is a picture of the front side of the VS-803PP rear spar. I’m very happy with how the rivets turned out.

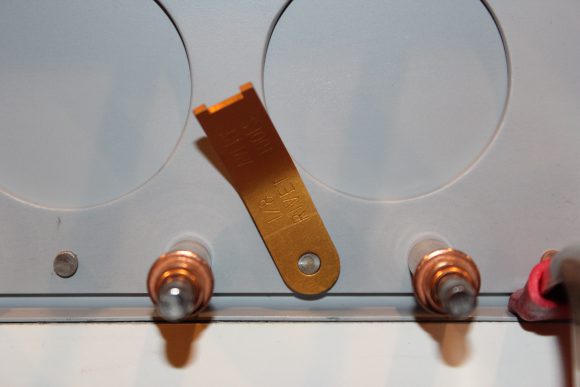

And checking my riveting with the Go-No-Go gauge shows that my work is acceptable.

Please comment, I love to hear from my readers. Thanks again for coming along for this ride, you make my work worthwhile.

Leave a Reply